Material Requirement Planning (MRP): [PDF]- Process, Inputs, Objectives, Advantages, & Disadvantages

Material Requirements Planning (MRP) is a basic digitally operated supply planning technique to help manage inventory. An MRP system enhances production process efficiency through proper estimation of needed materials and just-in-time delivery.

MRP helps manufacturers maintain low production inventory levels because they’re dealing with the manufacturing, purchasing, and delivery activities.

What you are going to learn?

How Material Requirement Planning (MRP) Works

An MRP system speeds up the manufacturing production process by figuring out what raw materials, subassemblies, and components are required, and when to complete assembling those into finished goods, based on demand and bill of materials (BOM).

Material Requirement Planning answers three basic questions;

- The first question is: “What is needed?”

- The second question is: “How much is needed?”

- The last question is: “When is it needed?”

MRP is basically a technique for trying to figure out the materials and items required to manufacture a specific product. It helps companies get a grasp of inventory needs while controlling both supply and demand.

In the case of interpreting raw data like bills of lading and the shelf life of stored materials, MRP gives meaningful information to managers about their requirements for labor and supplies, which can help companies increase their production performance.

Steps Involve in the Material Requirement Planning (MRP) Process

The MRP process can be divided into six steps:

1. Identifying Requirements to Meet Demand:

The first step of the MRP process is to figure out customer demand and the prerequisites to meet it. Using a bill of materials (BOM), MRP breaks down demand into different raw materials and components.

2. Checking Inventory and Allocating Resources:

This step consists of looking at demand against what you already have in inventory. The material re then distributes resources accordingly. In other words, the MRP allocates inventory into the specific areas it is called for.

3. Scheduling Production

Applying the proper production schedule, the system figures out how much time and labor are needed to complete each step of each building and when they need to happen so that the production can take place without delay.

The production schedule also determines what machinery and facilities are required for each step and generates the correct work orders, purchase orders, and transfer orders.

4. Monitor the Process

The last step of the process is to monitor it for any issues. The MRP can frequently alert managers of any problems and even suggest emergency plans in order to reach build deadlines.

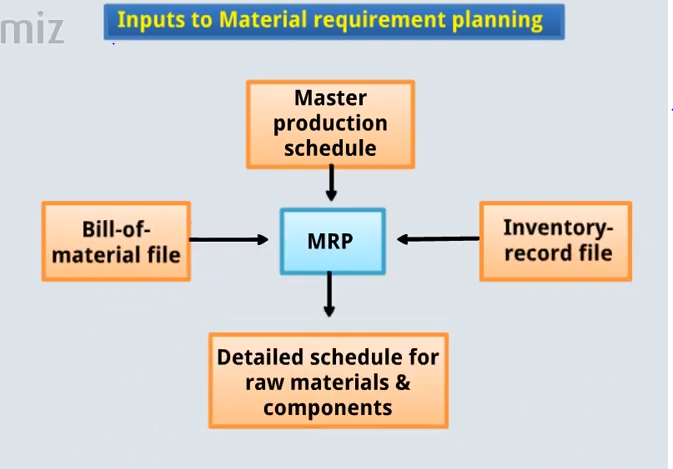

Data Needed for MRP System/ Inputs of MRP

There needed some data to apply efficiently Material Requirement Planning (MRP) in any organization;

Quantity: The system needed the user to input the amount of quantity required to reach specific demand schedules.

Shelf Life: The time that a product can remain in the warehouse is taken for the planning phase of a material requirement planning system.

End Item: MRP requires the user to specify what type of product is being manufactured and the demand level of that specific item.

Inventory Records: The records of accessible materials, work status, work process, and completion status.

Bills of Materials: It is basically a centralized source of information comprising a list of items used to manufacture a product and the directions on how to do so.

Objectives of MRP System

The main objectives of the MRP system are:

- It defines the quality and timing of finished goods ordered.

- It Calculates manufacturing, inventories, work-in-process, and packing lead times.

- It determines the time required for material planning, sub-assemblies, and components.

- It controls inventory by ordering materials.

- Improves customer service by meeting the promised delivery schedule.

- Decreases inventory expense by reducing inventory levels.

- Improves plant operating efficiency.

- Faster response to market change.

Advantages of Material Requirement Planning System

There are some advantages to using this system. Here are some of them;

1. Proper Implementation:

The key advantage of an MRP system is that by applying consistent discipline, you can get the benefits it delivers. The MRP system surely gives you a far better outcome than acting casually, as many do. MRP takes time and patience before the result present themselves.

2. Improved Internal Communication:

A material Requirement Planning system acts as a business communication framework, bringing all units into the same information field.

With correct data inputs, some systems also can constantly update the balance sheet of the company, making the life of accountants also very smoother. All collected data can be helped tremendously when making several business decisions.

3. Production Planning:

MRP system detects bottlenecks in the production line caused by a reduction of material or security. When it happens, the system can recommend a reroute to the manufacture of a different product where materials are available. MRP focuses efforts on a specific production phase at the expense of another phase deficient in raw materials and parts. MRPs help manufacturers design their production lines.

4. Work Scheduling:

Basically, work scheduling maintains active production time, foreseeing the required output and obedience to the production schedule. MRP draws a larger image of the production process using the available inventory. Managers’ can utilize this information to direct hourly operations, tools, and labor tasks, and even predict labor time and operational expenses.

5. Resource Management:

Maintaining control and preparing information about the raw materials’ availability and desired outcome also gives the manufacturer a thought of other resources to engage in the procedure. Information from the material requirement planning system suggests to the manufacturer what supplies are required at what time and when additional labor is required. Thus it helps to maintain the efficiency of an organization.

6. Data Management and Documentation:

manufacturing involves the preparation, research, and presentation of a huge amount of data and MRP helps manufacturers in managing this information. MRP processes and documents inventory data, purchase data, deliveries, and cash flow data into invoices, receipts, reports, lists, and other structured presentations.

7. Other Benefits of the MRP process:

Here are some other benefits of the MRP system:

- It increases labor productivity.

- Reduces customer lead times.

- Increases customer satisfaction.

- Economic purchasing.

- Time-saving.

- Eliminates critical tasks.

- Improved scalability.

Disadvantages of Material Requirement Planning

Besides advantages, there are some significant disadvantages of ERP systems that could affect your business.

1. Data Accuracy Risk:

The significant risk of an MRP system is that the data you have to put into the system must be consistent and correct, otherwise, it could deliver underwhelming or bad outcomes.

2. High Cost and Complexities:

Implementing an MRP system consumes a lot of money and you can face a lot of complexity. MRP system needs to spend considerable effort on installing necessary equipment, maintenance of necessary equipment, software, testing, and eliminating errors.

3. Dependability:

Material Requirement Planning is solely dependent on inputs it receives from other systems or departments. If there is a problem or error in the input then the whole output for material planning also be inaccurate.

4. Time Consuming:

The MRP system is a lengthy process as it takes too much time to train employees and deal with complexities.

Pingback: Manufacturing Resource Planning (MRP II): [PDF Inside] Elements, Advantages, Disadvantages, MRP I VS MRP II - EDUCATIONLEAVES

Pingback: Enterprise Resource Planning (ERP): [PDF Included] Types, Advantages, Disadvantages, Modules, Features - EDUCATIONLEAVES