Whenever a customer places an order with a store, a process begins that runs in the background until they finally receive their product. This is called the order management process.

Order management is all about tracking the orders coming into a retail business and managing the processes required to fulfil them. It consists of the cycle of people, processes, and suppliers to create a positive customer experience.

This process does not seem too hard when you establish a new business. At that time, a few orders come in each day and you can quickly fulfil them by yourself. But likely obstacles can arise as sales grow, channels multiply, we add products to your inventory, and your customer base expands.

An order management system can help eliminate bottlenecks for you as your e-commerce store grows.

What you are going to learn?

What is Order Management?

Order management covers everything from the point of receiving an order right through to delivery as well as after-sales experience and dealing with any relevant returns.

It also covers keeping a record of the customer, which may include their purchase history, payment method, and volume of orders. Sales departments give notice to the warehouse to fulfil the order, and they then shipped the order to the consumer.

When you scaling the business, it’s important to automate and streamline the order management process — otherwise, the sheer number of orders coming in will eventually overwhelm you.

What is an order management system?

An order management system offers you a one-stop-shop to view and manage all consumer’s orders in one place. Some systems offer two-way sync that makes sure that order information is passed between your order management system and your e-commerce platform while providing you with visibility into the entire process.

It can help automate the flow of sales order information to every piece of the retail supply chain. That means you can track the entire activity of a customer order, from buying the product to delivery and even returns.

How does the Order Management process works?

Order management processes start whenever a customer places their order and pays money for it. They sent order details to the store’s inventory, where warehouse workers manage the picking, packing, and shipping. This process ends with the store checking in with the customer to figure out whether they were happy with their purchase.

The Order Management process can be divided into three stages: receiving a customer’s order, fulfilling the order, and then handling the after-sales processes.

Let’s discuss separately how these stages work:

Stage 1. Receiving the customer’s order

The first stage of an order management process starts when a customer places an order with your business. Receiving the order includes accepting the order from the customer and collecting payment for it. After that, it forwards the details of the purchase to your warehouse so your staff can start working on getting the products ready for shipment.

Customers place orders from different places, at different times, across every available channel. To streamline this process in one place, you need multichannel order management or omnichannel fulfilment tool that can automatically push the related information from your e-commerce store to your order management system.

Stage 2. Fulfilling the customer’s order

In the second stage, you fulfil your customer’s order. We can split this stage into three distinct steps:

Step 1. Picking

Fulfilment of an order starts with the picking process, where the items are retrieved from the warehouse. The warehouse is lined with shelves, and they stock each shelf with different products, so warehouse workers need to pick the right items for order quickly and accurately. Once the items have been picked, sent to a packing station to be packed.

Step 2. Packing

The packing station packing items and sending them off for shipping. They are also in charge of using the right packaging materials for each product so that it comes to the customer unbroken and in good condition.

For example, extremely delicate items like glassware need to be packed with bubble wrap or air pillows and should be in a properly sized box to avoid wasting packing material.

Step 3. Shipping

After picking and packing the correct order, the next step is to ship it. Warehouse employees attach the applicable shipping label and invoice to the order. Then they mark the order as shipped in all of your sales channels and send shipping confirmation and order tracking emails to the customer.

If the product is out of stock, you left with two choices: you can either turn the customer away or postpone the order delivery to a later date using backordering or dropshipping.

For backordering, you place a purchase order with your supplier for the product that is out of stock. Then the supplier will give you a date when they will receive the new stock, and you give your customer a tentative date to expect to receive their order.

With dropshipping, you forward the customer’s order to the supplier and they deliver the product directly to the customer without sending it to you first.

Stage 3. Handling the post-sales processes

The last stage of the order management process is handling the after-sales processes. This is where businesses follow up with customers to receive feedback and make sure that if they are satisfied with their purchase and manage any returns and refunds if they are not.

Staying in continuous contact with loyal customers can help you figure out why customers keep coming back to your store, and how you can build up the lifetime value of each customer. Meanwhile, identifying recurring problems can create a feedback loop that helps your business improve.

Why order management is important?

Order management influences virtually every system and process in supply chain management. Most companies which are no longer contain order management within their organization. They involve various partners such as parts and components suppliers, assembly and packaging services or distribution centres, making it easy to lose visibility and control of the order.

This results in costly manual processes to complete and deliver the order without errors. An Order Management System can help to control costs and generate revenue by automating manual processes and reducing errors.

Externally, order management has a direct impact on how a consumer recognizes a business or brand. In an omnichannel environment, customers expect a smooth experience. A customer may order online but have questions and complete the order through a call centre.

As the order is being fulfilled, the customer hopes to see updates like emails along the way. If there is any problem arise, they may wish to return it through a physical channel such as a store. Each point in the process presents an opportunity to provide a great customer experience and boost retention and revenue. The omnichannel journey also presents opportunities to make up-sell and cross-sell recommendations and grow revenue.

Problems to Avoid in Order Management

Many shippers find that when the business takes off, many problems can appear because of the number of people involved as a company grows. As one-off incidences, problems such as late placement of orders or wrong items delivered are apparently harmless, but these can spoil the reputation of a business and lead to unhappy customers.

In order to avoid delays and mistakes in delivery and obtain a higher cost of sales, e-comers must streamline their business processes. Inspect the flow of orders by cross-referencing in the different departments until it reaches the payments.

Here are some examples of ineffectiveness in the order management process:

- Delays in order submission.

- Data entry mistakes that may lead to fulfillment mistakes.

- Difficulties in manual processes and from old software systems.

- Outdated inventory information during ordering process that leads to backorders.

How to Improve Your Order Management Process?

The major source of the problems is outdated systems that have efficiencies not that much greater from the manual filling of order forms, how the forms are passed on, and even the team of data encoders encoding the selling order.

Let’s discuss some examples of other ways to solve the situation:

- Automating filling order forms will eliminate errors in resignation of orders and double entry, such as having Amazon Punchout, which populates fields instantly in Amazon business and adds it to your purchase order.

- Integrating all sub-processes by linking digital order solutions into existing ERPs or purchasing a good software platforms.

- Updating traditional solutions or work systems that affect the fulfillment operation.

- Avoid backorders and delays of order processing by providing customer service reps with updated inventory information, keeping inventory data accessible to them in real-time for strategic selling.

Key Order Management process metrics

With any position of your business, KPIs (key performance indicators) for your order management process are very useful. Maintaining a close eye on these allows you to see what part of the process is weak and needs more attention.

Let’s discuss some of the key metrics to help do this for your order management process:

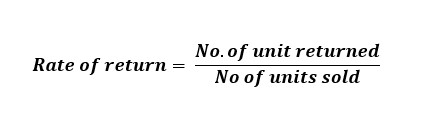

Rate of return

The rate of return gives an insight into how often items are being returned by customers. A low rate of return means the product is performing well. If the return rate is high, you have to find out the exact cause of poor results and strategies put in place to resolve that problem.

The rate of return is the ratio of the number of units returned to the number of units sold.

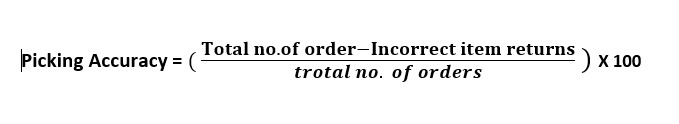

Picking accuracy

A poor picking accuracy results in unhappy customers, negative reviews and you have to pay extra to fix the errors. Therefore, it is crucial to keep track of the picking accuracy.

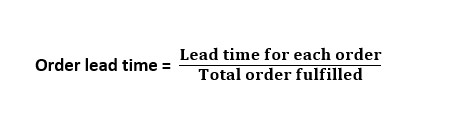

Order lead time

This measures the time between a customer placing an order and actually having the product delivered.

Minimising the lead time can have a tremendous impact on customer satisfaction and so is well worth tracking. At the same time, it’s important to not sacrifice accuracy or quality in this process.

Determinate order lead time based on the average time of all the orders that were fulfilled.

Purchase frequency

Purchase frequency is simply a measure of the frequency of orders per customer over a period (usually a year).

This is more significant for some businesses than others. But it’s an efficient way to track the quality of any follow-up and nurture campaigns and the customer experience.