What is Supply Chain Management (SCM)? – Working, Importance, example, PDF

We can define supply chain management as “Design, planning, execution, control, and monitoring of supply chain activities to create net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand and measuring performance globally“.

What you are going to learn?

What is Supply Chain?

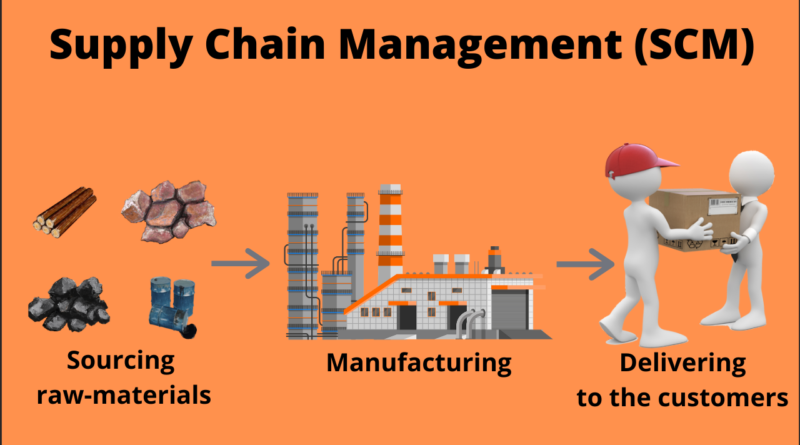

A supply chain is a combined network of individuals, organizations, resources, activities, and technologies involved in the manufacture and sale of a product or service. A supply chain starts with the delivery of raw materials from a supplier to a manufacturer and ends with the delivery of the finished goods or service to the end consumer.

Organizations develop supply chains so they can reduce their costs and remain competitive in the market.

Download Supply chain Management PDF

What Is Supply Chain Management (SCM)?

Supply chain management (SCM) is the handling of the entire production flow of goods and services that includes all processes for converting raw materials into final products. It involves the active streamlining of a business’s supply side activities to maximize customer value and gain a competitive advantage in the marketplace.

Supply Chain Management practice depends heavily on industrial engineering, systems engineering, operation management, logistics, procurement, information technology and marketing, and strives for an integrated approach. It is the broad range of activities required to plan, control and execute a product’s flow from materials to production to distribution in the most economical way possible.

How Supply Chain Management Works?

Typically, SCM attempts to control or link the production, shipment, and distribution of a product. By managing the supply chain, companies can cut excess costs and deliver products to the consumer faster. This is done by keeping tighter control of internal inventories, internal production, distribution, sales, and the inventories of company vendors.

In SCM, the supply chain manager coordinates the logistics of all aspects of the supply chain, which comprise five parts or stages:

1. The plan or strategy

Companies require to plan and manage all resources needed to meet customer demand for their product or service. They also require designing their supply chain and then determine which metrics to use in order to ensure the supply chain is efficient, effective, deliver value to customers, and most importantly meets the enterprise goals.

2. The source of raw materials or services

Companies must choose suppliers to provide the raw materials and services needed to create their product. After suppliers are under contract, supply chain managers use a variety of methods to monitor and manage buyer-supplier relationships. Key processes of sourcing include ordering, receiving, managing inventory, and allowing supplier payments.

Supply chain collaboration begins at this stage and is important throughout the supply chain management process.

3. Manufacturing

At this stage, they manufacture products. It includes scheduling the production, test for quality, ensuring it followed compliance requirements, package for shipping, and schedule for delivery. Most enterprises test the quality, production output, and worker productivity to ensure the enterprise creates products that meet quality standards.

4. Delivery and logistics

The delivery stage refers to logistics and focuses on getting finished goods to consumers, in whatever mode of transportation is needed. This involves coordinating customer orders, scheduling delivery, dispatching goods, invoicing consumers, and receiving payments.

Many companies outsource large parts of the delivery process to specialist organizations, particularly if the product requires special handling or is to be delivered to a consumer’s home.

5. The return system for defective or unwanted products

The return stage includes all product returns, including defective products and products that will no longer be supported. The supplier needs a responsive and flexible network to take back defective, excess, or unwanted products. If the product is defective, it needs to be reworked or discarded. If the product is simply unwanted or excess, it needs to be returned to the warehouse for sale.

The supply chain manager tries to minimize shortages and keep costs as low as possible. They recommend improving productivity, quality, and efficiency of operations.

Typical SCM Key Performance Indicators

A key performance indicator or KPIs are crucial components of a successful SCM strategy. They identify expected performance standards and allow supply chain managers to measure performance and identify areas needing attention. They are useful for measuring performance improvements. Common KPIs include:

- Cash to cycle time: The time between paying for raw materials and receiving payment for goods delivered, which matters in determining working capital requirements.

- Perfect order rate: The number of orders delivered without flaws, which is a crucial metric for organizations seeking perfection and often broken down further by function.

- GMROI: The gross margin return on investment, measuring the amount of gross profit gained on the cost of inventory used, which is a metric commonly used in retail.

Supply Chain Management example

Walmart and Procter & Gamble worked together in the late 1980s and are the classic case of supply chain collaboration. Before these two companies began working to connect their supply chains, retailers and manufacturers received little information. After Walmart and P&G showed that shared information reduced cost, other retailers became more willing to consider the possibility. In the early 1990s, Walmart formalized its Retail Link system and deceived other retailers to connect.

Over time, the Walmart POS system could aggregate sales of individual P&G products at each store. When the POS showed that inventory for a particular product had gone down to a predetermined threshold, the Walmart distribution centre got a notification to ship additional product to the store.

As inventory in the Walmart distribution centre fell to its threshold, the P&G distribution centre was automatically notified to ship more product.

Today, this uninterrupted flow of information helps P&G to determine when to manufacture and ship products to Walmart. By avoiding manufacturing too much inventory and by automating the billing and payment process, both companies enjoy low costs.

Functions Of Supply chain Management

Supply chain management is a cross-functional way that includes managing the flow of raw materials into an organization, certain aspects of the internal processing of materials into finished goods, and the flow of finished products from the organization and toward the end consumer.

As organizations seek to focus on strengths and become more flexible, they reduce control of raw materials sources and distribution channels. These functions are increasingly being outsourced to other firms that can perform the activities better or more cost effectively.

The effect is to extend the number of organizations involved in satisfying customer demand while reducing managerial control of daily logistics operations. Less control and more supply chain partners lead to the creation of the concept of supply chain management.

The aim of supply chain management is to improve trust and collaboration among supply chain companions, thus improving inventory visibility and the velocity of inventory movement. In this section we have to communicate with all the suppliers and after that we have to take some comparisons before placing the order.

Importance of Supply Chain Management

An effective supply chain management processes minimizes cost, waste of resources and time in the production cycle of a company.

Over the last two decades, the supply chains of manufacturers and retailers have become ever more strongly tied up. The industry model has become a just-in-time supply chain where retail sales automatically signal replenishment orders to manufacturers. As collaboration has improved, additional data from supply chain partners has allowed companies to use advanced analytic tool to further improve results.

For examples:

Identifying potential problems before they occur

Sometimes a customer orders more product than the manufacturer can deliver, the buyer can complain of poor service. This leaves the buyer feeling unimportant and convinced the manufacturer’s service is poor. It disappointed manufacturers who assume the shortage before the buyer may offer a substitute product or other incentive to keep the buyer happy.

Optimizing price dynamically

Seasonal products, particularly fashion products, have a limited selling life. Any that don’t sell by the end of the season is scrapped or sold at heavy discounts to clear the warehouse. Airlines, hotels, and other companies with a limited, but perishable product, change prices dynamically to meet market demand. While this is more difficult with clothing and other products where the supply can vary widely, similar forecasting techniques can improve margins.

Improving the allocation of available to promise inventory

Analytical software tools help allocate resources and schedule work based on the sales forecast, actual orders and assured delivery of raw materials. Manufacturers can confirm a product delivery date when the order has placed, substantially reducing incorrectly filled orders.

Circular Supply Chain Management

Circular Supply Chain Management or CSCM is the structure and coordination of the organisational functions like marketing, sales, R&D, production, logistics, IT, finance, customer service, etc. across business units and organizations to close, slow, intensity, narrow, and dematerialise material and energy loops to minimise waste and emission leakage out of the system, improve its operative effectiveness and efficiency and generate competitive advantages.

By reducing resource input and waste leakage along the supply chain and configure it to enable the recirculation of resources at different stages of the product life cycle, it can achieve potential economic and environmental benefits. These comprise e.g. a decrease in waste management cost, reduced emissions and resource consumption.

Benefits of Supply chain Management

Supply chain management creates several advances that convert to higher profits, better brand image and greater competitive advantage. These benefits include:

- Better ability to predict needs and meet customer’s demand;

- Better supply chain visibility, risk management and predictive capabilities;

- Less process inefficiencies and less product waste;

- Enhancements in quality;

- Increased sustainability, both from a societal and an environmental standpoint;

- Lower overhead;

- Improvements in cash flow; and

- More efficient logistics.

Skills and capabilities needed for Supply chain Management

Supply chain specialists need to have knowledge of managing supply chain functions, such as transportation, warehousing, inventory management, and production planning. In the past, they have to just focus on logistics skills such as shipping routes, warehouse equipment, distribution centre, fuel cost, etc.

But recently, supply chain management extends to logistical support across firms and management of global supply chains.

What is the Extended supply chain?

The extended supply chain consists of all companies that contribute to making a finished product. This means that the extended supply chain comprises the suppliers to your suppliers and the customers of your customers.

When companies face supply chain problems, the initial reaction is to ask the supplier about the situation. However, organizations that monitor the extended supply chain have the opportunity of reaching back through the primary supplier to the company that supplies items to the primary supplier.

As an example, if a popular baseball hat is not available from the manufacturer, the natural reaction of the store manager is to contact the manufacturer. However, if the retailer monitors the extended supply chain, the store manager would know the manufacturer was having difficulties getting the brim. If additional brims will not be available to the manufacturer immediately, the retailer would have time to request a different supplier.

Pingback: what is Order Management process? - EDUCATIONLEAVES

Pingback: What is Inventory management? - EDUCATIONLEAVES

Pingback: What is Operations Management? (PDF included) Definition, Responsibilities, Nature, and Benefit of OM - EDUCATIONLEAVES

Pingback: What are Mergers and Acquisitions? M&A Definition, Example, Types, Forms, and Transactions - EDUCATIONLEAVES

Pingback: Enterprise Resource Planning (ERP): [PDF Included] Types, Advantages, Disadvantages, Modules, Features - EDUCATIONLEAVES

Pingback: Law of Demand and Supply: [PDF Included] Curves, Importance, Conditions, & Factors Affecting Demand and supply - EDUCATIONLEAVES

Pingback: What is Supply chain Management ( SCM )? | What is Supply chain? - AskField

Pingback: What is Supply chain Management ( SCM )? | What is Supply chain? - EasyToolsSupplies