Maintenance and reliability employees are always seeking “perfect production” This is very difficult since unexpected problems arise even in the best-planned facilities.

Total productive maintenance or TPM is the process of using machines, equipment, employees and supporting processes to maintain and improve the stability of production and the quality of systems.

Total productive maintenance (TPM) is a strategy that operates according to the concept that everyone in a facility should take part in maintenance, rather than just the maintenance unit. This approach uses the skills of all employees and seeks to incorporate maintenance into the everyday performance of equipment.

It is a comprehensive approach to equipment maintenance that aims to achieve perfect production. That means;

- No Breakdowns

- No Small Stops or Slow Running

- No Defects, and

- No Accidents.

What you are going to learn?

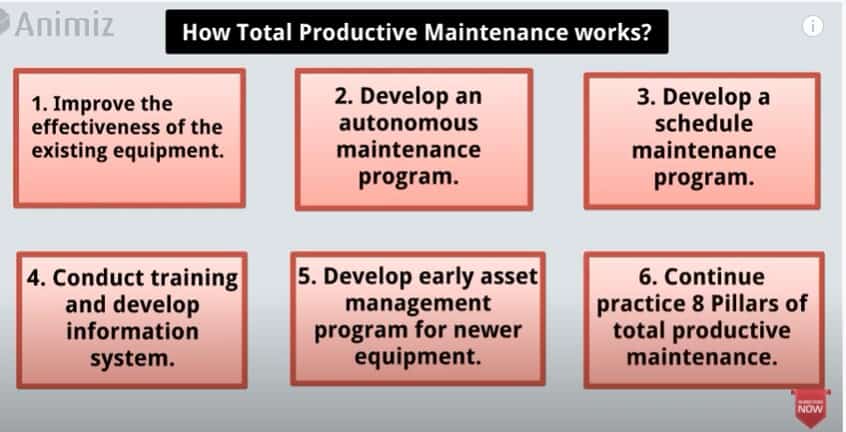

How does Total productive maintenance works?

- Improve the effectiveness of the existing equipment.

- develop an autonomous maintenance program.

- develop a schedule maintenance program.

- Conduct training and develop information system.

- develop early asset management program for newer equipment.

- Continue practice 8 pillars of total productive maintenance.

Let’s discuss,

8 pillars of Total Productive Maintenance

5-s Method in the workplace

Total Productive Maintenance is based on eight pillars, which are based on the 5-S methodology. The 5-S methodology is an organizational method based on five Japanese words and their meaning:

- Seiri, which means organize: Its aim for eliminating clutter from the workspace.

- Seiton, which means orderliness: That means ensures order by following “a place for everything and everything in its place”.

- Seiso, which means cleanliness: clean the workspace and maintain it that way.

- Seiketsu, which means standardize: standardize all work processes, making them steady.

- Shitsuke, which means sustain: that means continually reinforcing the first four steps.

The eight pillars of total productive maintenance focus on proactive and preventive approaches to help in improving equipment reliability. The eight pillars are: autonomous maintenance, focused improvement, planned maintenance, quality management, early equipment management, training and education, safety, health and environment, and TPM in administration.

Let’s discuss each pillar separately:

1. Autonomous maintenance:

Maintenance and care for equipment should start with the people using the equipment. The empowerment of operators to work on minor maintenance tasks effectively allows the maintenance teams to focus more on specialized assignments.

Autonomous maintenance means ensuring your operators have proper training in routine maintenance like cleaning, lubricating and inspecting, as well as placing that responsibility solely in their hands.

- Autonomous maintenance gives operators greater control of their equipment.

- It increases operators’ knowledge of their equipment.

- They ensure equipment is well-cleaned and lubricated all the time.

- maintenance team identifies emerging issues before they become failures.

- Frees maintenance personnel for higher-level tasks.

2. Focus improvement

Also known as the Japanese term Kaizen, Continuous Improvement promotes the attitude of progressing towards zero losses and zero defects. Through small but continuous modifications to processes, the overall effectiveness and efficiency of the organization are built up. Focused improvement looks at the process and finds out ideas for how to improve it.

- It diversifying team members allows them for the identification of recurring problems through cross-functional units.

- It also combines knowledge from across the company so teams can see how processes affect different departments.

3. Planned maintenance:

Planned maintenance exercises are essential to avoid equipment breakdown. Planned maintenance involves analyzing metrics like failure rates and historical downtime and then schedule maintenance tasks based on these predicted or measured failure rates.

- Planned maintenance significantly reduces examples of unexpected stop time.

- It alloys most maintenance to be performed at times when equipment is not scheduled for production.

- And reduces inventory through better control of wear-prone and failure-prone parts.

4. Quality maintenance:

All the maintenance programs and strategies in the world are meaningless if the quality of the maintenance being performed is incompetent. The goal of quality maintenance is to determine any causes of variations from zero-defect production.

- It does this by proactively detecting the source of errors or defects, thus processes become more reliable, and producing products with the right specifications for the first time.

- The biggest benefit of quality maintenance is it reduces cost by prevents defected products from moving down the line, which could lead to a lot of rework.

5. Early equipment management:

Early equipment management takes the practical knowledge and overall understanding of manufacturing equipment gained through total productive maintenance and applies it to correct the design of new equipment.

Construction of equipment with the input of people who use it most allows suppliers to improve maintainability and how the machine operates in future designs.

6. Training and education:

Training and education fill the knowledge gaps necessary to achieve total productive maintenance goals. It applies to operators, managers and maintenance personnel. The idea of TPM is that everyone does their part to contribute to the overall productivity of the production process.

- Operators develop skills to regularly maintain equipment and identify rising problems.

- Maintenance personnel learn skills for proactive and preventative maintenance.

- Managers are trained on TPM principles and on employee coaching and development.

7. Safety, health and environment:

Maintaining a safe working environment means employees can complete their tasks in a safe place without health risks. To accomplish this, any solutions introduced in the TPM process should always consider safety, health, and the environment.

When employees come to work in a safe environment every day, their attitude towards the work tends to be better, since they don’t have to worry about this necessary aspect. This can increase productivity noticeably.

8. TPM in administration:

A good TPM program is only as good as the performance of its parts. Total productive maintenance should look beyond the plant floor by addressing and eliminating areas of waste in administrative functions like order processing, procurement and scheduling.

Administrative functions are often the first step in the entire manufacturing process, so it’s important they are streamlined and waste-free.

Example of total productive maintenance

The standards encouraged by TPM are deeply rooted in the involvement of personnel. The major factor that drives its success is the correct approach exhibited by the management, maintenance staff, and operators.

A TPM success story took place inside one of the largest beer brewers in Latin America, Cervecería Cuauhtemoc Moctezuma (CCM). Describing the meaning of TPM and how CCM applies it within the organization, plant maintenance manager Manuel Sanchez says, “It means we are all responsible for guaranteeing the total effectiveness of the equipment — maintenance, production, top management, human resources… everyone. “

The advantages of Total Productive Maintenance

Fewer breakdowns

When machine operators have an eye out for changes with their equipment, big issues are more likely to be detected early, before a breakdown occurs. More planned maintenance implies fewer failures. By implementing proactive maintenance activities, downtimes are minimized.

Lower manufacturing costs:

As overall equipment efficiency (OEE) increases, it also minimized manufacturing costs. Higher productivity leads to higher profits and reduced spending on equipment stoppage time and repairs.

A safer workplace

Maintenance technicians are much more likely to take risks when running to fix a breakdown, so fewer breakdowns mean a safer workplace. When everyone keeps maintenance in mind, problems can be discovered and solved well before they become potentially dangerous situations.

Better overall performance

If everyone in a facility is keeping an eye on maintenance, small fixes will stop going undetected, which helps you move away from breakdown maintenance and get backlog under control. It takes the pressure of minor problems off the maintenance team so they can concentrate on the bigger problems, which increases the overall performance of your facility.

Less unplanned maintenance

With carefully planned and scheduled maintenance, equipment is extremely well maintained. TPM empowers all plant personnel to take ownership of their equipment and machine, and maintenance is a positive investment for them. Since TPM makes maintenance personal, assets are better cared for.

Terms related to TPM

Corrective or Breakdown Maintenance

In Corrective or Breakdown maintenance repairs are performed after the equipment is out of order and it can not perform its normal function. In that case, the maintenance department comes into action and makes needed repairs after checking. They do not attend to the equipment until another breakdown occurs. Read more >>

Preventive Maintenance

In simply we can say, Preventive maintenance is maintenance performed before the breakdown occurs. It tries to decrease problems of breakdown maintenance (that means problems like excessive delay in production, time loss, productivity loss, etc). Read more >>

Predictive Maintenance

Predictive Maintenance (PdM) is one type of maintenance that checks the condition and performance of machinery during normal running operations. By doing so, maintenance personnel can determine possible defects and fix them before they result in a failure. Read more >>

1 thought on “What is Total Productive Maintenance (TPM)? 8 pillar of Total productive Maintenance, PDF”